The Idaho National Laboratory has emerged as a crucial partner for rare earth companies in Wyoming and Montana.

At the same time, new technologies for extracting valuable minerals from coal waste could open other pathways to reduce Chinese rare earth dominance, according to testimony at a U.S. House Small Business Committee hearing Tuesday.

The hearing revealed the federal laboratory's expanding role beyond nuclear energy research into critical mineral processing.

Harvey Kaye, executive director of U.S. Critical Materials, told lawmakers that his Montana company has partnered with Idaho National Lab to develop breakthrough processing technologies.

"Our plan is to be able to extract from our deposit literally this year, to be able to stand on the steps of the White House and/or Congress with a bag of gallium, rare earths that were found in Montana, processed with American technology and available for the defense of this country and indeed the free world," Kaye said.

Gallium is a soft, silvery metal used in LEDs, solar panels and Blu-ray technology, among others.

The company has partnered with Idaho National Lab (INL) to develop breakthrough processing technologies for getting gallium and other rare earth minerals to market — without relying on China.

"China controls 90% of the global downstream rare earth market impacting the rest of the world's supply chain and giving them significant control and restricting America's access to materials vital for manufacturing and defense capabilities," Aaron Dowd, CEO of Rare Earth Salts, testified.

In a follow up interview, Rare Element Resources Vice President Kelli Kast told Cowboy State Daily the purpose of the hearing was to help spur a thriving rare earth industry nationwide, “because we only have the one mine in America today.”

Rare Element Resources is developing its operation in Upton, which includes a mine and processing facility.

“How do we ensure a secure domestic rare earth supply chain from an ‘all-of-the-above’ strategy,” said Kast, who attended the hearing.

“They asked the witnesses to testify about ideas and concepts that can help stand up the domestic supply chain. So, several concepts were put on the table,” she said.

Coal Innovation

Specifically, the hearing showcased developments by research institutions beyond INL that want to extract rare earth elements from coal waste, an approach that could significantly expand domestic supply without new mining.

Laura Stoy, CEO of Revalia Chemical, described her company's work recovering rare earth elements from a variety of existing coal waste streams.

"At Revalia, we are pioneering new chemical extraction technologies to recover valuable rare earth elements from industrial wastes including coal fly ash and other coal combustion byproducts," Stoy testified.

The scale of coal-based rare earth potential dwarfs traditional reserves, she said, touching on the type of rare earth development going on at places like the Ramaco Resources’ Brook Mine near Ranchester, Wyoming.

"Researchers at (University of Texas at) Austin estimate that there are 11 million metric tons of rare earths in coal ash alone," Stoy said, compared to just 2 million metric tons in conventional U.S. reserves.

"Oak Ridge National Lab found millions of tons of rare earths in phosphogypsum," she added, highlighting additional waste stream opportunities.

Phosphogypsum is a solid waste byproduct generated during the manufacturing of fertilizer.

"Our core innovation is that our method both extracts the rare earths from the starting material and does the separation from the bulk in one single step," she explained.

Her company's process works with multiple waste streams, including mining tailings and acid mine drainage, Stoy said.

Congressional Interest

Committee Chairman Rep. Roger Williams, R-Texas, signaled legislative support for coal-based extraction, mentioning potential tax incentives.

"I have a bill … offering for rare earth elements production tax credits $9 on a ton of coal for refuse, $20 per kilogram on rare earth elements extracted and sold from coal," Williams said.

The coal waste approach could complement traditional mining efforts in Wyoming and Montana, providing multiple domestic pathways to challenge Chinese market control.

Williams emphasized the strategic importance of the effort.

"We have one (established) mining company of rare earths elements in the United States, MP (Mountain Pass) in Southern California. One processing refinery. What are we doing, right?" he said.

Lab Partnership

INL’s partnership with U.S. Critical Materials has yielded concrete results, according to Tuesday's testimony.

After a year of collaboration, the lab has "accomplished the goal of setting forth the flow diagrams and the methodology for a process that we call an electrochemical membrane reactor," Kaye testified.

The laboratory's involvement could dramatically accelerate development timelines, he said.

"Idaho National Labs has agreed that they can cut a year off the development of the plant that we are putting online that will be a full-blown demonstration plant, at least two tons a day," Kaye said.

INL also validated the quality of Montana ore through extensive analysis, confirming it is "very low in thorium and very high in grade," Kaye said.

Thorium is a radioactive element, so ore with low levels of that element helps the company avoid nuclear regulatory requirements that could delay development.

Kaye described the partnership's environmental focus.

"It is environmentally conscious. It has the ability to process rare earths in an efficient environmental manner," he said of the electrochemical membrane reactor process.

Wyoming Investment

Ken Mashinsky, president and CEO of Rare Element Resources in Upton, told the committee his company has invested more than $170 million in developing what the U.S. Geological Survey recognizes it as a world-class rare earth deposit.

"RER is a publicly traded company with a critical rare earth deposit and state-of-the-art innovative rare earth processing and separation demonstration plant in Wyoming," Mashinsky testified.

The company has built significant infrastructure with government support.

"RER, with partial funding from the Department of Energy and the State of Wyoming, have constructed and will soon begin operating our over $66 million demonstration plant that is intended to prove our separation technology on an industrial scale," he said.

Mashinsky described the company's innovative approach.

"Our goal is to compete with China in rare earth production and also create a path for processing and separation that is economically and environmentally superior, adhering to all U.S. environmental regulations while supplanting the environmentally detrimental and costly steps in conventional Chinese technology," he said.

The Wyoming operation faces logistical challenges in its small-town location.

"We live, we are, our process and our facility is in a very small town of Upton, Wyoming, 800 and something people," Mashinsky said. "We're relatively close to other population centers but the ability to recruit STEM employees is difficult in that area and that's a very important issue for us."

Montana Deposits

U.S. Critical Materials operates at the Sheep Creek site in Ravalli County, Montana, where the company controls 339 claims covering approximately 11 square miles.

The deposit contains what Kaye described as "the highest-grade rare earths ever found in America, averaging 9% up."

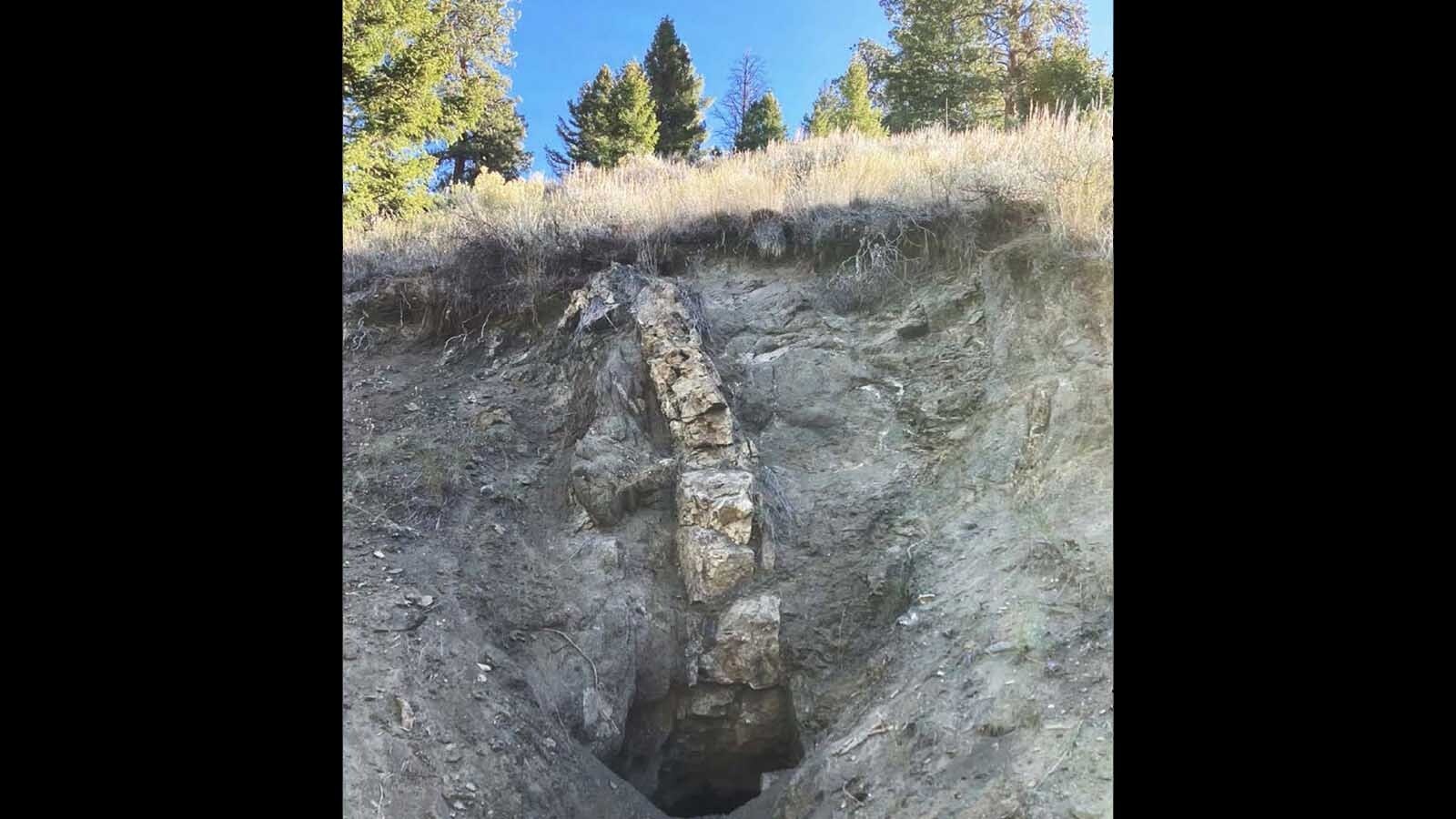

Kaye provided geological details about the unique formation.

"It is an extraordinary deposit because of its carbonatites. And carbonatites, geologically 150 million years ago, have come up from the earth, have penetrated through fissures, and have extended above the surface," he said.

The extensive exploration shows promise throughout the deposit, he said, including samarium, which is used in magnets for electric motors — as well as gallium.

"Gallium is a mineral, a critical mineral, that has 3,800 military uses. The Chinese have banned it to export about a year ago. We have 180 to 380 parts per million," Kaye said.

Kaye continued to emphasize the national security implications of the Montana mine.

"The F-35 requires 920 pounds of rare earths. A submarine is 5,000. The new F-47, which is now being proposed, requires large amounts of rare earths,” he said, noting that not only aircraft, but the technology used to track them requires these elements. “The newest radar that we're working on requires rare earths.”

David Madison can be reached at david@cowboystatedaily.com.