A drilling rig in Sweetwater County punched through nearly 3.5 miles of Wyoming rock, reaching a total vertical depth of 18,437 feet to complete what's now the deepest Class VI carbon storage well ever drilled in the United States.

The Sweetwater Carbon Storage Hub, a collaboration between the University of Wyoming's School of Energy Resources and Frontier Infrastructure Holdings, successfully completed drilling operations for its second deep-characterization well last week — what the partners described as a key milestone in advancing commercial-scale carbon sequestration in Wyoming.

Class VI wells represent the most heavily regulated category of underground injection wells in the country, according to the Environmental Protection Agency.

These wells are used to inject carbon dioxide deep into underground rock formations for permanent storage, a process known as geologic sequestration.

Under the EPA's Underground Injection Control program, Class VI wells must meet rigorous criteria for site characterization, well construction, monitoring and financial responsibility to ensure the stored CO2 remains safely trapped far beneath drinking water sources.

While most Class VI wells operate at depths of about a mile, the Sweetwater project has pushed those boundaries to reach formations that promise even greater storage potential and safety margins, according to the team lead by Fred McLaughlin, director of UW's Center for Economic Geology Research.

Wyoming Drilled

To drilled the deepest hole of its kind ever in the U.S., the university turned to the Wyoming experts in deep drilling for the Sweetwater project.

When oil and gas operators in Wyoming's Powder River Basin need to drill lateral wells stretching 3 miles or more through underground formations, they turn to Cyclone Drilling of Gillette.

The drilling contractor has emerged as the region's go-to specialist for the most technically demanding extended-reach projects, working with three major operators pushing the boundaries of what's possible in energy extraction.

"They all have 3- and 3-plus-mile laterals, and they have discussed incrementally longer and longer laterals," Paul Hladky, vice president of Cyclone Drilling, told Cowboy State Daily in June.

Hladky described the ambitious drilling programs his company is executing for Continental Resources, Devon Energy and Anschutz Exploration Corp.

"Whether it be that 4-mile milestone or not, I don't know if it's just a milestone or if there's value there,” he said about the ever-evolving underground world of horizontal drilling.

Hladky said extended-reach wells are becoming the new standard in the Powder River Basin, and Cyclone Drilling is meeting that demand with equipment upgrades.

For the Sweetwater Carbon Storage Hub, Cyclone deployed the deep-penetrating capabilities of Cyclone Rig 35.

Why So Deep

McLaughlin said the record depth wasn't just about setting milestones, it was driven by practical necessity and geological advantage.

"The reason you have to drill so deep out there, there's already existing gas wells that are very deep and this industry — the carbon management industry — cannot impede existing mineral rights,” he said. "You sometimes have to drill below existing hydrocarbon wells to assess Green River Basin storage resources."

The depth also brings other benefits, McLaughlin said.

"The deeper you store CO2, the denser it gets. So you kind of get more bang for your buck with respect to having more space," he said. "You do get kind of a bonus — that volumetric bonus from going that deep is one of the reasons to do it.

“Safety-wise, you've got so much overlaying rock that helps seal those fluids in. And that's another reason southwest Wyoming is interesting.”

Pointing to ExxonMobil's Shute Creek facility in Lincoln County, McLaughlin said, “That fluid they're producing — helium and CO2 and methane — that's been stored down there probably for 60-70 million years."

That natural storage provides a geological seal of approval for the location.

"If you're putting gas into a place that's held gas for millions of years, you feel a sense that you're in the right place, that’s the right formation," McLaughlin said. "That's one of the things we look at in our basins and our geology.

"Do we know that there's already been long-term fluid containment? That's an ideal piece of real estate to start looking at initially."

Deep Time

One more added benefit for McLaughlin and his team: The project has been an entertaining adventure back in time.

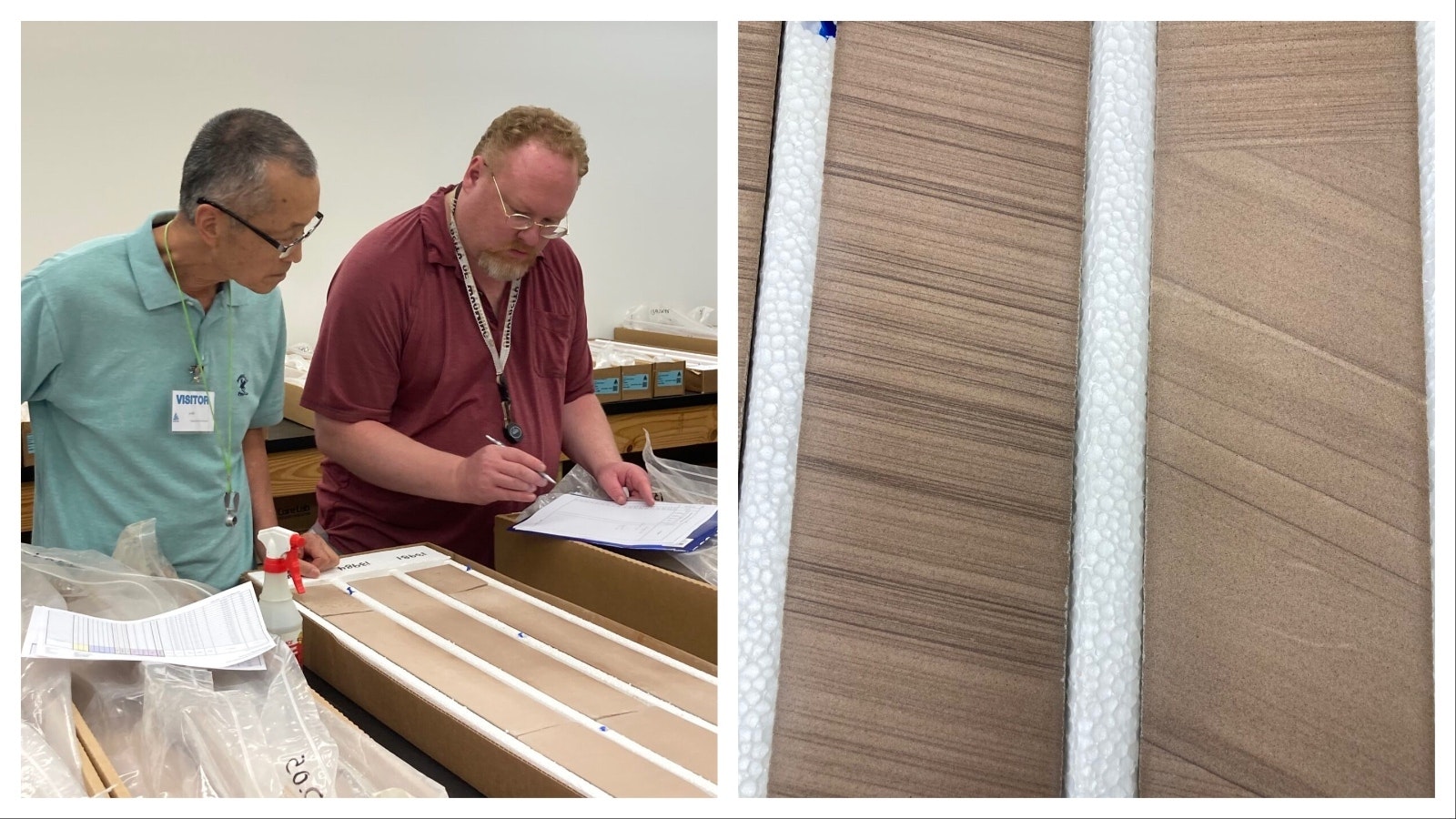

"We pulled up some core that hasn't seen sunshine for over 200 million years," McLaughlin said. "In this case, we can still see fossils from when Wyoming was an ocean back in the day. So even though it's been super deep and really hot, cooked pretty well, you can still see little shell fragments.”

The drilling also revealed remnants of Wyoming's sandy past, evidence of when the state was covered by ocean waters and later resembled the Sahara Desert.

"Very similar to the Killpecker Dunes today, just north of the project site," McLaughlin noted.

Business Opportunities

Frontier Infrastructure Holdings, a portfolio company of Dallas-based Tailwater Capital, brings financial backing to the project.

The firm has raised more than $5 billion in committed capital since inception and has executed more than 285 transactions representing over $27 billion in value, according to its marketing materials.

The project is part of the U.S. Department of Energy's CarbonSAFE Initiative and aims to establish a commercial-scale carbon capture, utilization and storage hub in Sweetwater County, capable of delivering long-term, secure CO2 storage for industrial emitters across the region.

Robby Rockey, president and co-chief executive officer of Frontier, said the project went as planned.

"Successfully drilling and testing a second well on this project has confirmed our preliminary interpretation of the reservoir and is a major step forward to validate the region's storage potential," Rockey stated.

"This deeper well gives us a more complete picture of the subsurface, reinforcing our commitment to building scalable, practical carbon solutions for Wyoming's key industries,” he said.

Other Options

Even with a record-setting well practically in their backyard, not every industrial operation in the region sees carbon capture as the right fit.

Jon Conrad, former environmental and governmental affairs manager for Tata Chemicals in Green River and a Wyoming state representative, said his company is actively working to reduce its carbon footprint, but not through carbon sequestration.

"Right now, it's the economics. Obviously to capture that carbon for operations is incredibly capital intensive," Conrad said.

Instead, Tata Chemicals is pursuing a different path entirely: converting from coal-fired boilers to nuclear power through small modular reactors, with the first deployment planned for 2031.

"We look at a plant that's, at our age, we've been on here over 50 some years, the technology to upgrade and to retrofit all of our different exhaust components — it's unbelievably expensive," Conrad said. "Thus, we are going to reduce carbon by seeking or utilizing nuclear steam and power."

Back at the Sweetwater Carbon Storage Hub, the project continues to work toward key regulatory and engineering milestones.

The next phase will focus on detailed modeling, permitting and preparation for eventual injection operations, all under the EPA's oversight requirements for Class VI wells that include monitoring and post-injection site closure protocols.

McLaughlin said he's proud of the team's achievement.

"The data collected from this well is essential to confirming the feasibility of the SCS Hub and advancing Wyoming's position in the emerging carbon economy," he said.

David Madison can be reached at david@cowboystatedaily.com.