CHEYENNE — A byproduct of Dyno Nobel's ammonia manufacturing operations — carbon dioxide — will be captured and commodified by Reliant Processing and sold to different sectors of the food industry, the companies announced Friday.

They say the new partnership will transform waste CO2 into jobs and keep food items bought online cool when they land on your doorstep.

Texas-based Reliant Processing will build a new liquid CO2 and dry ice plant at Dyno Nobel's industrial complex on Otto Road in Cheyenne, creating at least 30 jobs, the companies say in the announcement.

"We are thankful for the opportunity to work with the community of Cheyenne and Dyno Nobel to capture the CO2 and use it in the essential food, beverage and industrial gas markets," said Scott Vanderburg, CEO of Reliant Holdings, as part of the recent groundbreaking ceremonies.

"This is really good news," Dale Steenbergen, CEO of the Greater Cheyenne Chamber of Commerce, told Cowboy State Daily on Friday, adding that it’s an example of ways CO2 can be modified and create local jobs.

The partnership leverages Cheyenne's position as a manufacturing hub where Dyno Nobel's 60-year-old facility produces ammonia, urea, nitric acid and other industrial products, including explosive chemicals for the state’s coal industry.

Rather than releasing CO2 as a waste product, the new arrangement will capture those emissions and process them into liquid CO2 and dry ice.

Cool Shipments

Anyone in Wyoming who enjoys fizzy drinks or likes to order T-bone steaks online might be served by the products created.

Liquid CO2 is used to carbonate sodas, and dry ice packs keep any perishable click-and-ship product like steaks, salmon or flowers sold online fresh in the box.

"This investment ensures a supply for CO2 and dry ice in the Rocky Mountain region," said Mark Ohlmeier, director of sales for Reliant Processing. "I'm not aware of other CO2 companies that are doing this in the southern Wyoming area.”

Ohlmeier told Cowboy State Daily the new facility "will employ 15 full-time employees once it's operational, and then we will have an additional 15 to 20 distribution employees that are associated with the transportation and truck maintenance."

Steenbergen noted that the partnership aligns well with the local workforce's existing skills.

"They might not know about dry ice, but they know about pipelines and construction," he said, making them a good fit for the job opportunities Reliant Processing anticipates.

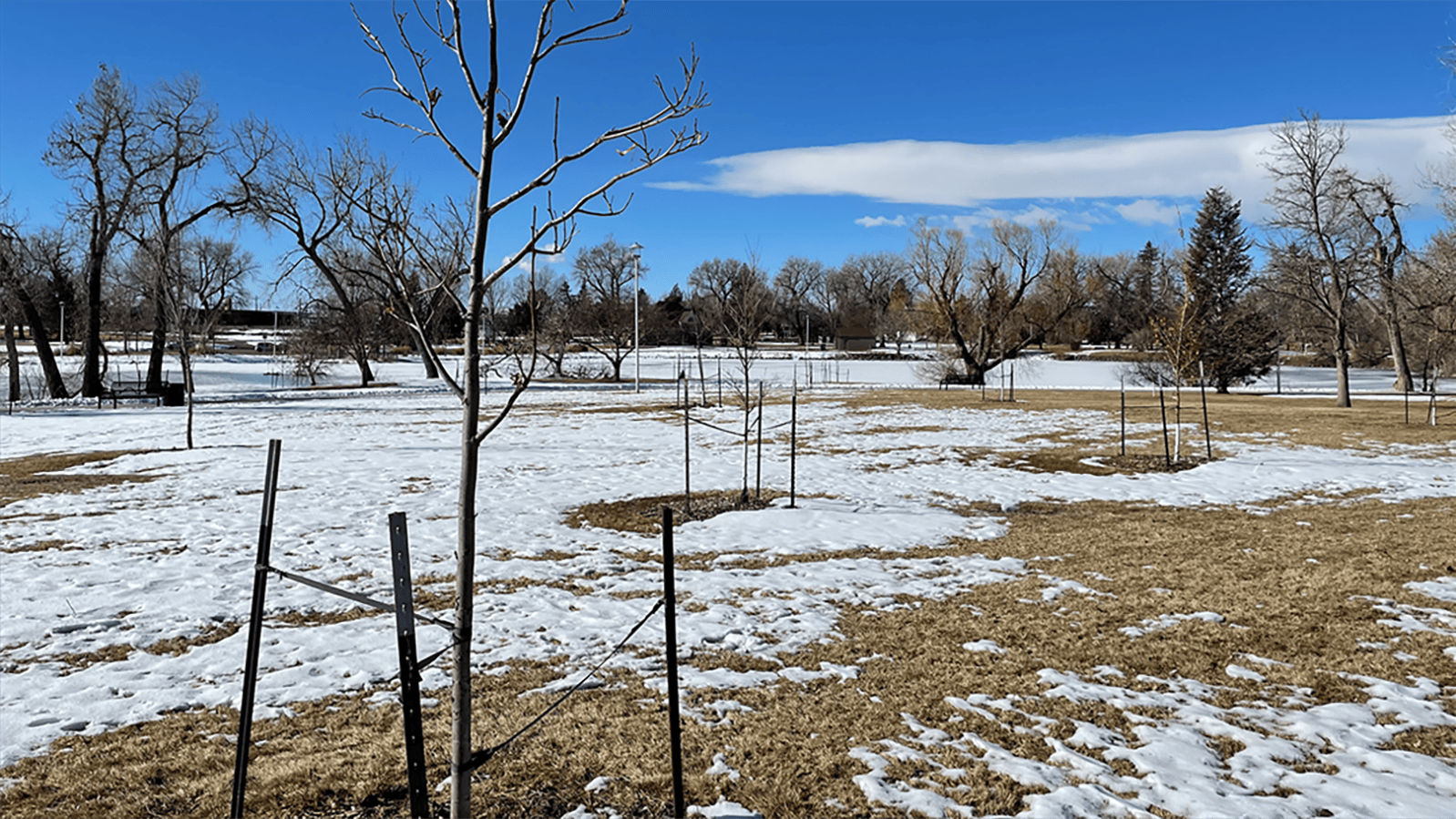

The partnership also aligns with Dyno Nobel's broader sustainability initiatives at its Cheyenne facility, which sits on 3,000 acres of rolling hills and grassland 3.5 miles west of the city, according to press materials from the company.

The plant recycles water, captures carbon dioxide from ammonia production for use in fertilizer manufacturing, and produces diesel exhaust fluid (DEF) to reduce harmful emissions from diesel vehicles.

Peter Henderson, site manager at Dyno Nobel's Cheyenne facility, emphasized the broader economic impact.

"This is a large industrial manufacturing site and employs 200 local employees,” said Henderson in a press release. “To have Reliant invest on our site is a welcome investment in our Cheyenne community."

A Reliant press release went on to describe the enterprise as causing “zero harm” to the environment.

The new CO2 production and distribution facility’s location at the crossroads of two major interstate highways and the Union Pacific railroad positions it well for regional distribution, according to the release.

Cowboy State Daily has covered Dyno Nobel before, including a March 2024 investigation into missing explosive materials, namely 30 tons of ammonium nitrate.

David Madison can be reached at david@cowboystatedaily.com.