In Hawk Springs, there’s another field of dreams sprouting in a potentially big way for Wyoming’s hemp industry.

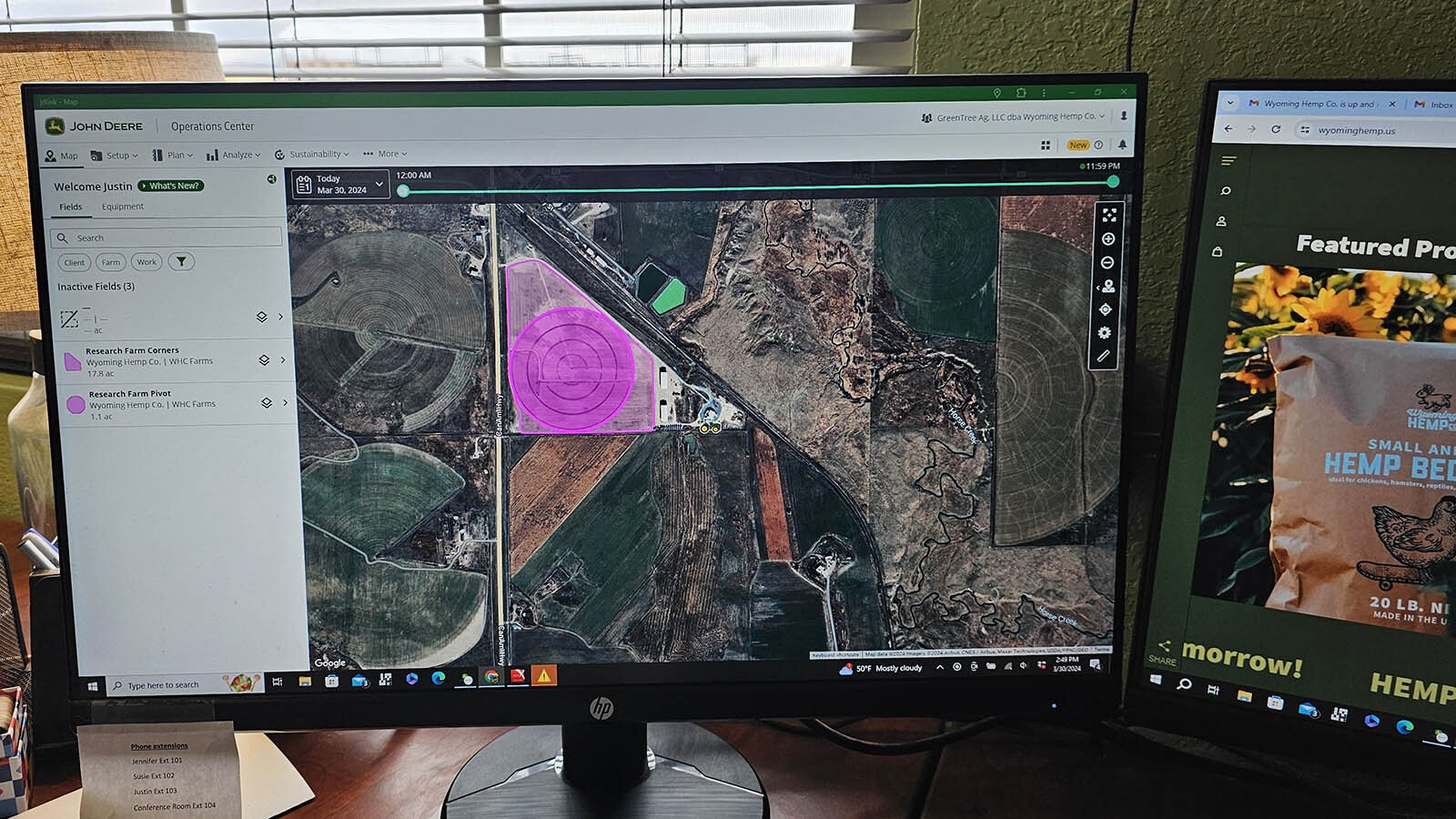

That field includes a research farm belonging to Justin Loeffler, who is placing a big bet on the future of hemp fiber in Wyoming.

His farm won a Natural Resources Conservation Service (NRCS) grant, which helped Loeffler put in center-pivot irrigation for what will be the site of some variety testing with various hemp manufacturers.

Loeffler has already set up a middleman processing plant, kind of like a grain elevator, but for hemp, to process hemp fibers in bulk. That could help create this middle link that the hemp sector has been missing for a while between farmers and manufacturers.

But to really get going, Loeffler believes he needs information and data that he’s just not finding available in the United States.

“Come to find out, all the real hemp research right now is being done out of country,” Loeffler told Cowboy State Daily. “Uruguay, Asia, Canada …”

Loeffler acknowledged there are people growing hemp in Wyoming, but their scale isn’t what he’s looking for.

“I can’t take that data and send it to my farmers who have 60-foot air seeders and thousands of acres to get up,” he said. “We just can’t do that. We’ve got to have real data.”

So, rather than wait for that data to come along from somewhere else, Loeffler has decided to take matters into his own hands, and he’s betting the information will be useful in a wider region than just Wyoming.

“The old motto is if it works in Wyoming, it’ll work anywhere,” Loeffler said. “So, if we have a research farm here, and we’re partnering with New West Genetics down here, and we’ve got Horizon Hemp seed up here, and we’ve got Kanda, which is based in Brooklyn.

“We’re bringing these groups in here, and we’re finding out what varieties actually work in our elevation, our geographical region, which is knowledge that our (hemp) farmers need.”

Helping With Reclamation Projects

The research farm will also consider reclamation projects, which Loeffler believes should be another very useful application tailor-made for hemp.

“Hemp is a longer-lasting biodegradable,” Loeffler said. “When they put in roads, pipelines, new construction, all of that requires dirt work in reclaiming that soil. Seeding it to grow, erosion control, all of those things. Right now, those things probably cost around $5,000 an acre to put down.”

Loeffler is betting a hemp reclamation study on his research farm can show that hemp would not only cost less per acre, but would be less labor intensive long-term and would last longer than the present materials more commonly chosen.

Wyoming has a lot of reclamation projects, Loeffler added, and in his mind, those projects would all be that much better if they were supporting Wyoming agriculture by using a Wyoming-grown product.

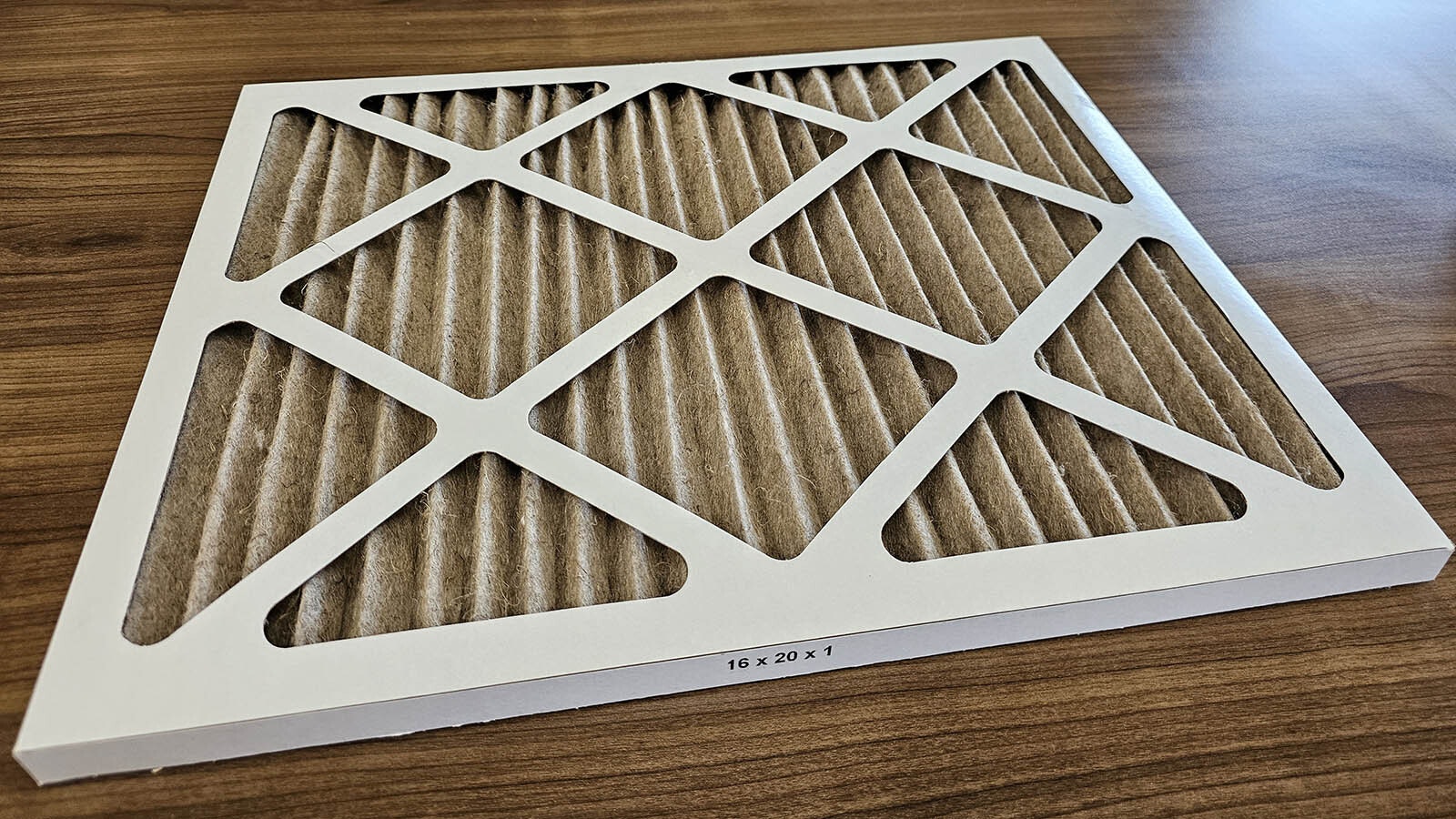

Loeffler is also continuing to develop hemp bedding materials for livestock, which he believes is probably hemp’s best toe in the door right now to get something started that can grow and diversify in the future into things like insulation, non-allergenic filters and building materials like hempcrete (a concrete-like building material made from hemp).

So, while he’s figuring out which varieties grow best in Wyoming, he can also be looking at which varieties work best for bedding and other purposes.

Hemp can be used to create superior bedding, Loeffler added, one that particularly helps with mites and ammonia mitigation.

One Step At A Time

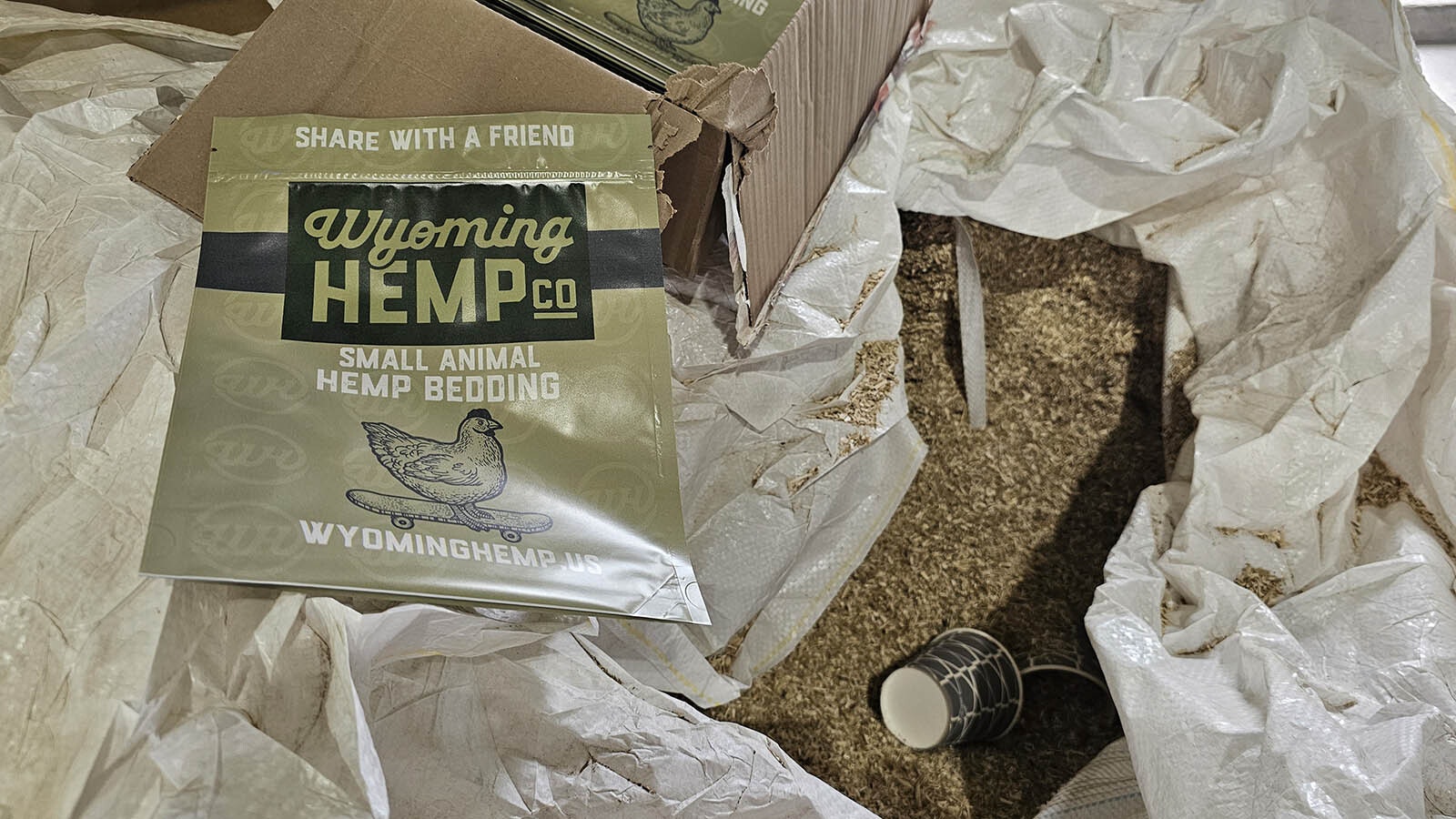

Recently, Loeffler went on a little shopping spree, buying up all the hemp bedding products he could find and comparing them to what he’s been able to produce with his own custom-designed processor, which he says can do 30 tons an hour at a fraction of the cost of other hemp processing units on the market.

That makes him the fastest processor around in not just the Cowboy State, but all the states surrounding it. And the processor he’s built is easy to set up in other locations, too, so he can scale up with demand.

What he found after examining other bedding products is that his own product is doing better than he had initially thought.

“We bought the No. 1 selling brand, Old Dominion, and it’s $140 a freaking bag,” Loeffler said. “And it says American made on the bag, but guess what happened when we opened it up? It’s actually made in Canada.”

Other bags that said dust-free turned out to be not so dust-free, and he discovered that some of the hemp bedding companies are even letting their hemp rot a little bit to soften the lignin, which is the woody part of plants.

“That just makes it musty, though,” he said. “And that’s not great for livestock. So, there’s just misleading things and some mislabeling. The hemp industry is just broken right now.”

That gives Loeffler a toe in the door, though, to market a superior product to Wyoming ranchers on the way to creating the nuts and bolts he believes Wyoming’s hemp sector needs to realize its potential.

“Our product is $31.50 a bag,” Loeffler said. “And in our testing, it came in third for absorbency and cleanliness for dust.”

Loeffler said he’s implemented quality control measures since then to keep the product as dust-free as possible, and to ensure that it continues to stack up well against competition.

“We don’t need to conquer the world here,” Loeffler said. “We can just build our brand and focus on Wyoming. All our bedding is only going to be Wyoming-grown, and we’re just going to take care of our own folks first. Wyoming has a big enough demographic, because we have a huge animal base, and we have great farmers.”

Contact Renee Jean at renee@cowboystatedaily.com

Renée Jean can be reached at renee@cowboystatedaily.com.