CASPER — Inside the long warehouse-like building of High Country Fabrication, the skills of man augmented with machine technology produce what in many ways huge hollow tanks that resemble submarines.

Called “vessels,” the giant oblong objects also carry strange names that designate their use such as “fractionators,” “glycol exchangers,” “strippers,” “separators” and more. Many are 12-16 feet wide and up to 200 feet long.

While it doesn’t make much sense to build submarines smack in the middle of Wyoming, it makes perfect sense for High Country Fabrication to focus its humongous tanks on applications for oil refining, carbon capture, lithium battery production, hydrogen energy, mining and other heavy industries that are big in the Cowboy State.

It’s a lot like a grown-up erector set, except instead of building stuff with tiny tools they use tough steel torches and welders. In short, there’s literally nothing small time about the giant vessels the company makes.

“Our stuff is kind of big and meaty and takes months to build,” said Ryan Noel, sales manager for the company. “We are a big volume, high spec facility. We move kind of like big dinosaurs, just big projects. It’s not the quick fast assembly spitting little things out.”

The company’s roots go back to founders and welders Ed Reed and Dennis Polk, who operated out of a 3,000-square-foot rented facility in 1978. Then, they focused on building air compressor equipment, pipeline repair work and general welding jobs.

In the 1980s, the company moved and added to its workforce, space and equipment to become a niche fabricator of custom pressure vessels. By 1986, sales had exceeded $6 million.

Specialized Facility

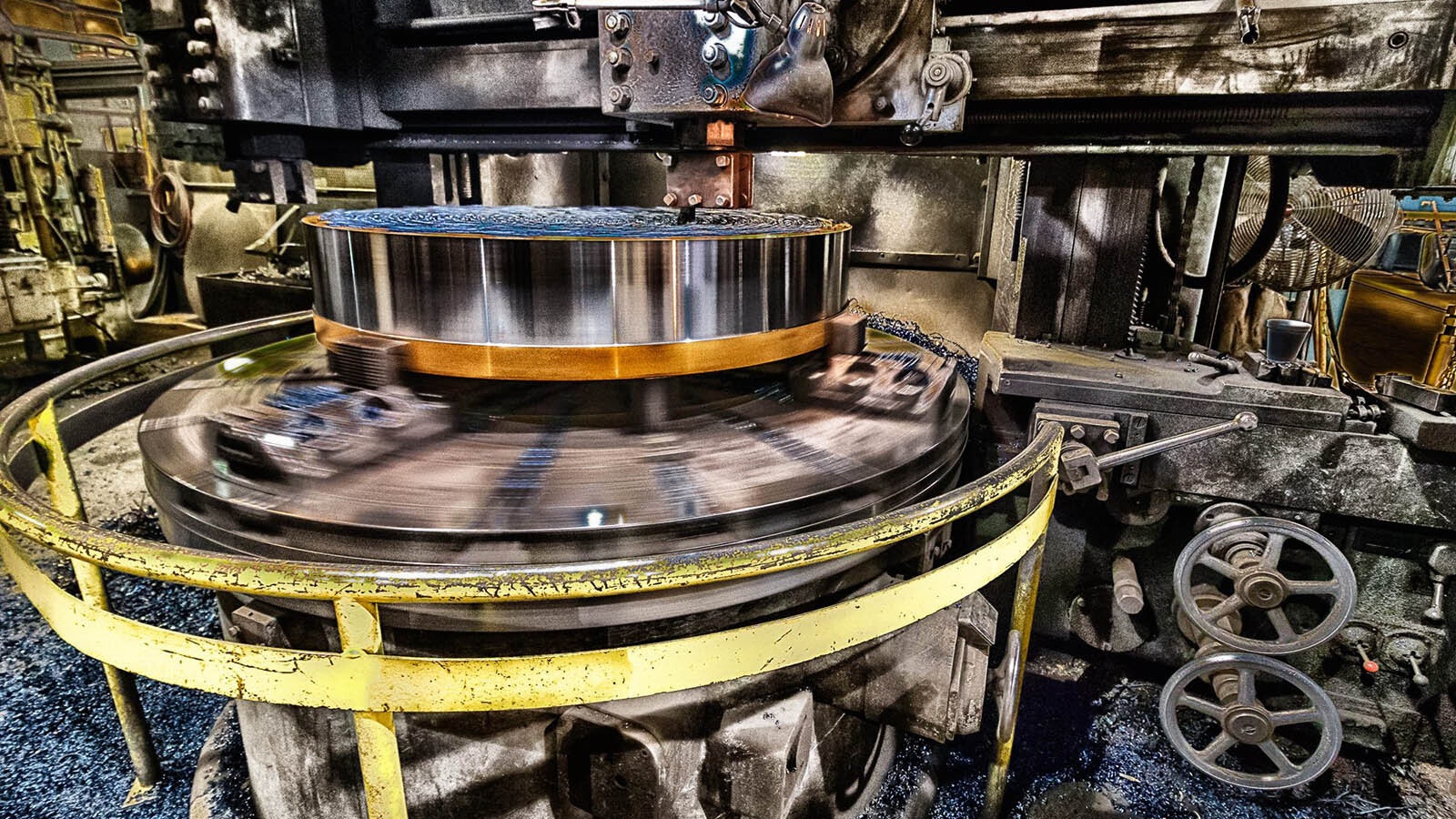

A move in 1989 and further expansion in 1994 set the company up for generating the annual $17 million to $20 million in revenue it brings in today. Over that time the company installed a 54-by-21-foot stress-relief oven, 422-foot fabrication bay, 150-foot-long paint bay and 6-inch thick steel roller.

“If you look at the history of our company, it’s really cool,” Noel said. “We have basically put some type of vessel in every refinery in the U.S. Now we are more diverse than we’ve ever been.”

As the energy sector evolved over the years, the company has moved to meet needs for lithium battery firms, carbon capture and other companies that are part of the green energy sector, such as those converting soybeans to diesel fuel and beef tallow to jet fuel.

What sets this Wyoming firm apart is its all-encompassing ability to engineer a specialty product with in-house engineers and manufacture it with welders capable of welding carbon steel, stainless steel, chrome or special alloys, Noel saidl.

“Most of our welders, we’ve trained ourselves. They are very specialized guys, we don’t want to lose them,” Noel said. “Some of them are 15- or 20-year employees.”

The shop’s founder Reed, in the early years of the business, bought a plate roll machine from a shipyard in Durbin, South Africa. The 800,000-pound device was insured by Lloyd’s of London, shipped to Houston and then to Casper on 13 trucks. It has allowed High Country to roll up to 6-inch cold steel to create the large-diameter pressurized rounded vessels it now sells.

Learning German

Since the machine had been manufactured in Germany, Noel said it came with a manual in German. The firm’s founder, Reed, was undaunted.

“Ed had to learn German to put it together,” he said.

The company’s technology has the capability to create heat exchangers inside vessels that are used in the energy industry as well as create specialized tanks that can handle up to 3,000 pounds of pressure.

There is a machine shop for drilling, boring and lathe work, a plasma cutting system for specialized cutting and beveling of steel, and a paint shop that handles specific paint needs for individual orders.

Noel said the firm uses an X-ray device or ultrasound testing to check each weld and its huge oven heat treats the vessels to ensure the end product is safe and meets specs. Vessels also receive hydrostatic testing with water to ensure viability.

While most of the company’s products are delivered out of state, Noel said High Country Fabrication has provided vessels for oil refining operations in Casper and Rawlins. It recently sent a 17-foot diameter intermediate absorption tower to Simplot Phosphates in Rock Springs used as part of a sulfuric acid production facility.

“Most of our vessels ship out of state,” he said. “Although those projects still generate local revenue, it’s exciting to be fabricating large projects right here in the state of Wyoming.”

Shipping Logistics

When it comes to shipping, there are two options for things this large — trucking or rail.

A spur from the BNSF Railway leads into the plant. To ship by rail, a 140-to-200-foot vessel requires a lot of thought. Noel said it can be about two-month effort working out the engineering behind loading and unloading.

“Then we go through with the railroad how to brace things, what routes we are taking, which turns we can make, which underpasses we can make,” Noel said. “But it can be a third of the cost of trucking sometimes.”

Trucking is a similar process that requires a lot of licensing and forethought. He said the firm typically subcontracts its trucking, but works closely with trucking firms to ensure their customers receive appropriate delivery in the timeframe needed.

When the company is approached for a large pressure vessel, Noel said the bidding process can take time because of the precision required for safety and quality.

“It can be months, it can be two years of going through the bid, clarifying things and refining it,” he said. “You are in high specification, potentially dangerous projects that you have to know exactly what you are doing.”

The company, a privately held partnership, has 64 employees and uses two shifts to keep production moving.

Noel said there are no other firms in the state that really compete with the scale High Country Fabrication does, but there are a few in Oklahoma and Texas. Their biggest competitor is in South Korea.

“The advantage for us being in Wyoming is the low labor rates, sales tax, having everything in house — all that really keeps us competitive,” he said.

The company sells about 130 vessels a year.

In addition to sales in the states, the High County has customers in Canada and overseas.

“We do a lot for the oil sands in Canada. They have been a great partner for us for years,” Noel said. Nigeria has been another place where the firm has sales.

“We will be very busy for the year,” he said.

Contact Dale Killingbeck at dale@cowboystatedaily.com

Dale Killingbeck can be reached at dale@cowboystatedaily.com.