CHEYENNE — Even in person, the color on Wyoming’s new license plates gives off a very close to black vibe — though the actual color is a deep, dark, navy blue.

Initial reactions to the new plates have been mixed, with some Wyoming residents describing them as “ugly,” while others just wonder what happened to Wyoming’s beautiful scenery featured on its plates.

Love or hate them, these new plates are coming off the press in Cheyenne by the thousands and will soon be bucking off all the old plates that feature the beautiful Green River Lakes region, framed by the Wind River Mountain range off in the distance, with the bucking horse logo center-plate.

While its blue might look black to many, the new plate actually takes its inspiration from Wyoming’s state flag and its colors, said Wyoming Department of Transportation spokesman Doug McGee.

“We feel like this is, of course, it’s our state flag,” he said when the first plate was previewed. “We have a lot of pride in that. We think it’s a great choice.”

Still Wyoming

The new plate still features the bucking horse logo, as required by state law. It floats over the top of the state seal and that iconic buffalo that’s part of the flag.

The bottom line of the license plate now includes travelwyoming.com, instead of the type of vehicle, the idea being to help promote tourism.

“It’s kind of nice to see something different,” Steve Lund told Cowboy State Daily. “There always seems to be a mountain scene on these. So, it’s kind of nice to see something new this time.”

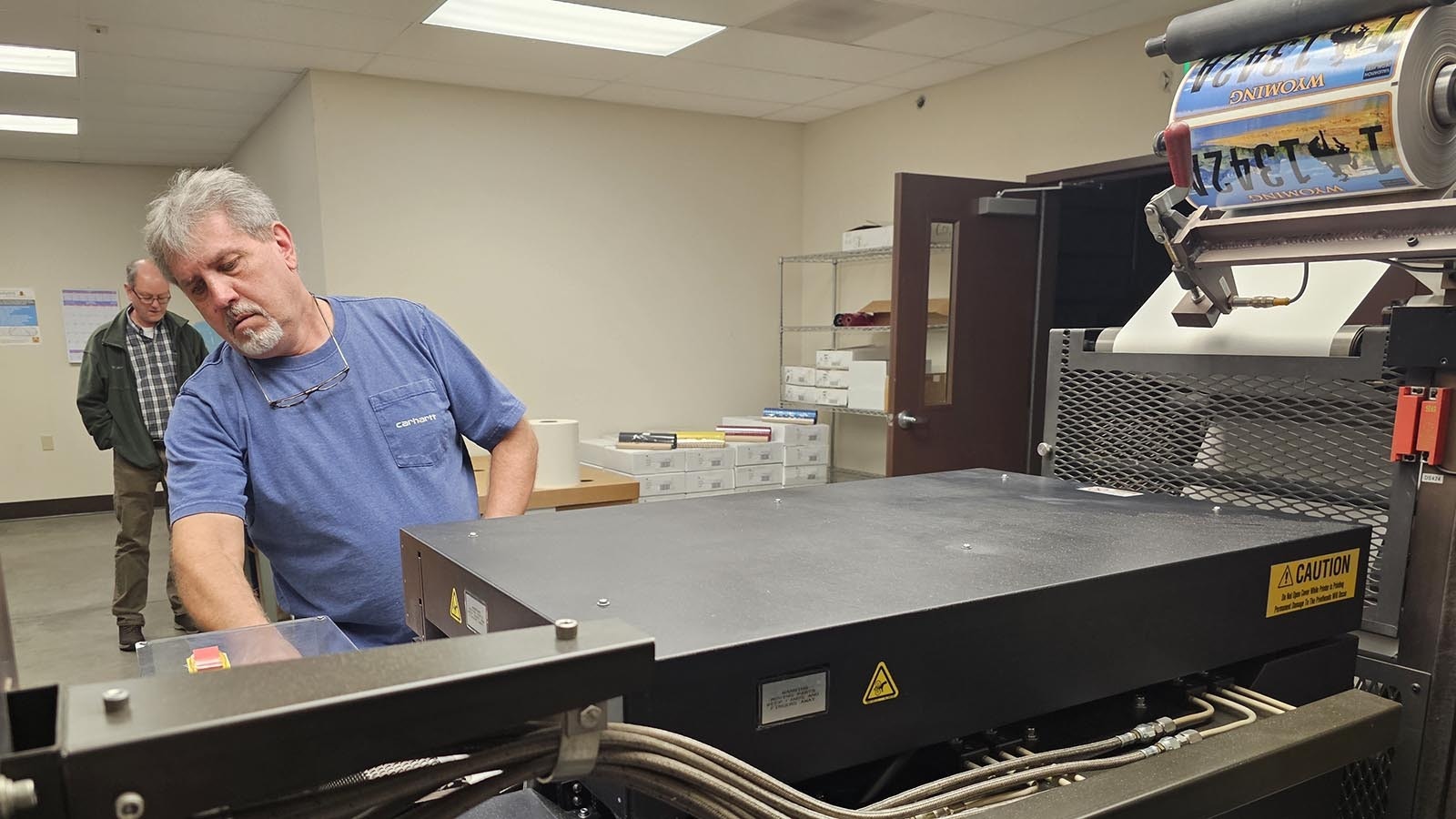

This will be Lund’s third go-round making the state of Wyoming’s license plates. Lund is part of a two-man operation that will print all 900,000 and some of the new plates Wyoming will need to eventually stick on each and every vehicle owned by Cowboy State residents.

Lund will buy 120,000 pounds of aluminum in rolls to accomplish the feat, which happens at an unidentified warehouse in Cheyenne.

“I call this Area 51,” he told Cowboy State Daily. “We’re in no-man’s land out here. Nobody knows we’re here, and that’s the way it’s supposed to be. We don’t want the general public to know where this is at.”

Every 8 Years A New Design

For those who don’t like Wyoming’s new plates, don’t worry. There’s a new plate design every eight years.

It is typically a hush-hush, top-secret process overseen by a commission, and then announced with a modicum of fanfare.

With so many different plates floating around, that’s created a number of license plate collectors. Some of the plates can be worth quite a bit if they are rare. World War II-era plates might be the hardest to come by, as they were printed on cardboard.

Lund told Cowboy State Daily a committee looked over several possible designs this go-round, and he made sample plates of each idea before commissioners made their selection.

All of those designs were simplified plates, some of them brown or beige. The driving force behind that simplification is making Wyoming plates easier for law enforcement to read from a distance.

The new plates have a slightly new numbering system as well. The first number on each plate is a county number, but the second letter will now identify the type of vehicle the plate belongs to, whether passenger car, truck or some other designation.

The remaining three to four numbers help produce a unique number that law enforcement can use to identify the owner of every vehicle in the state.

Right now, Lund is in a transition phase where he’s actually making both old and new plates for Wyoming’s counties.

“If you’re doing a 23-month registration, you can get the new plate now,” Lund said. “If you buy a new car and just want to do the year registration, then you’re still going to have the old plate.”

By 2025, all the old plates will be retired in favor of new plates, though.

Lund will then go to each county to collect up any unused plates with the old design. They will then be chopped up and recycled, which helps cut down on waste and defrays a little of his cost for new aluminum.

How The Plates Are Made

The giant hulking machines that make Wyoming’s plates are more than 20 years old. It’s a two-phase process, once a design has been chosen and created.

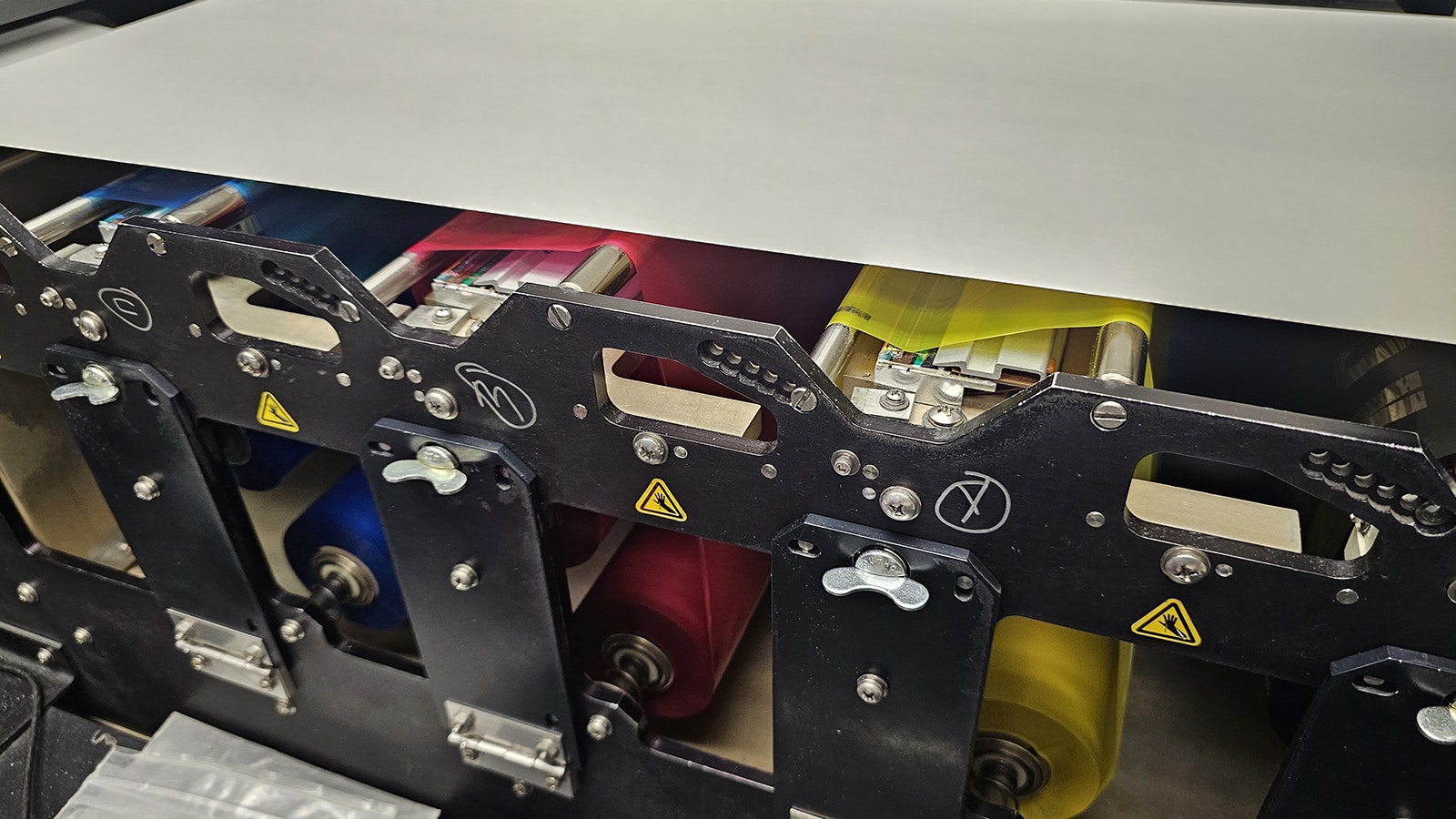

In the first phase, the license plate image is printed onto a decal that has a pressure-sensitive adhesive on the back.

This is deceivingly simple, though, because the final image is actually a composite of four different-colored films that are layered one on top of each other.

Black goes on the decal first, followed by yellow, then red and finally blue. The films are applied at a temperature that’s between 120 to 130 degrees Fahrenheit.

Much hotter than that, and the colors will bleed, ruining the decal.

Alignment is also important. Even a hair’s width difference will throw off the finished decal.

While the printing proceeds, the operator has to pay attention every second. At 30 decals printed per minute, it takes less than five minutes of inattention to rack up 100 ruined decals if something went awry.

The completed decals go to a second machine that will stamp the decal onto a thin aluminum plate. The sheet of aluminum comes off shiny metal rolls that only come in 40,000-pound increments.

The machine will not only smash the pressure-sensitive decal onto the aluminum plate, it will also cut holes for screws and round off sharp corners.

All the sharp corners and punched holes are eventually recycled.

Alignment is super important on this machine as well. The slightest bit off can produce a wrinkle, wasting plates at the rate of 40 per minute.

“Once it feeds in there and it gets a wrinkle, or if the aluminum is not perfect and it gets a small kink in it, then it just starts warping like a ribbon,” Lund said. “And it won’t stop until you stop it.”

In addition to making all of the state’s regular plates, Lund also prints all of Wyoming’s specialty plates, as well as the 3 million or so colored validation stickers needed each year to keep everyone’s license up-to-date, all of it happening in the Cowboy State’s very own little Area 51.

Renée Jean can be reached at renee@cowboystatedaily.com.