Have you ever wondered why the cargo bed of large pickup trucks is separate from the cab of said truck? The engineering reason, and the notable exceptions that proved it was needed, are an interesting story.

It all comes down to the physics involved in frame design. Pickup trucks are body-on-frame designs, which means the framework underneath the skin is in two separate parts: the base or chassis frame and the body frame. As the name for this type of design implies, the body is attached to the frame. In most cars and sport utilities, a unibody design is used, which integrates the frame and body into one unit.

The design of a body-on-frame vehicle like a pickup truck results in a higher center of gravity but also a stronger longitudinal strength for the vehicle. The frame’s design is called a ladder frame because that’s what it looks like when there’s nothing else attached to it. Two long rails are connected by cross members in what looks like a ladder. The cross members can be straight, bent, etc. to accommodate other items like engines and transmissions. In most body-on-frame designs, the engine and transmission are integral to the overall frame’s overall strength.

Because large pickup trucks are a body-on-frame design and because they are designed to handle heavier weights than other passenger vehicles, some flexibility in the framing needs to exist. If the frame is too tight all the way along either side, it will bend or snap when torsional (twisting) forces are applied. But it cannot bend too easily or it will become too flexible to handle the pressures given by trailers being pulled behind the truck.

This was learned over time as truck makers evolved their trucks’ designs to be more and more capable. Early trucks were merely sedans and large cars with a cargo bed instead of a set of rear seating. From the 1920s to the early 1940s saw many automakers using this basic idea as their way of offering both cars for the consumer and light-duty trucks for the commercial buyer. With the exception of large, dedicated truck designs, this was the norm until Ford and General Motors began offering half-ton pickup trucks to consumers. Those early designs didn’t always have a separate cab and bed. By 1950, however, that was the norm with few exceptions.

As capabilities got more robust, the problems of an attached cab and bed (single body) became apparent. Many models of the early Ford Ranchero and similar car-based pickups were subject to frame bending (slouching) and body crinkling from twists when consumers (inevitably) overloaded them. Modern car-based trucks don’t have these issues for several reasons, including reduced capability, shorter wheelbases, and smaller bed lengths.

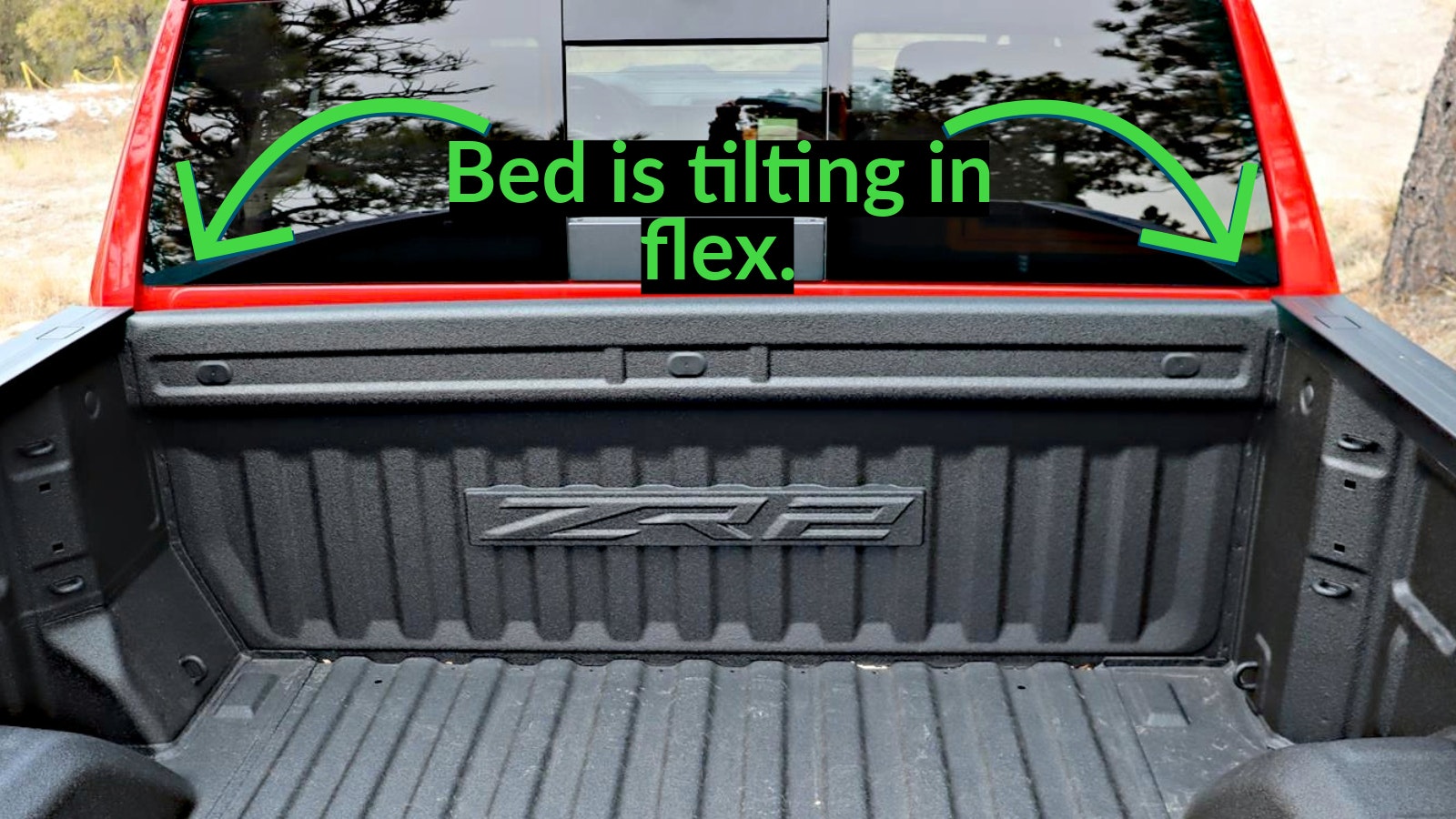

In a full-sized pickup truck, which may be expected to carry a literal ton of cargo and be able to pull several tons of trailer behind, a more flexible frame becomes key. Separating the cab (front portion) of the truck from the bed (cargo) portion, which is roughly the middle of the truck’s wheelbase, allows the bed to move independently of the cab, so frame twists to accommodate tough terrain or a heavy load does not bend or tear bodywork.

This is also, for those wondering, why sport utilities built on body-on-frame designs similar to pickup trucks will have lower cargo and towing capacities. Most SUVs have an independent rear suspension and no seam between the fore and aft of the vehicle. Making them less capable when it comes to weight bearing.

Another reason cargo beds are usually separated from the cab in a pickup is a practical one. When using a pickup truck to do truck things, the bed can be subjected to a lot of abuse. Scrapes, dents, slams, and smashes are commonplace. When repairs need to be done, it’s a lot easier and cheaper to replace an easily removable part (such as the truck bed) than it is to cut it off and re-attach a replacement (as with a fender). By the same token, it’s easier to modify or replace a truck bed with a different one to match a job to be done (such as a utility or flat-bed). Many heavy-duty pickups are sold as chassis cabs, which is the working truck without a bed on the rear portion of the frame. Then the customer can opt for whatever they need without having to remove an existing bed.

These are the two greatest reasons for separation between cab and bed. Today’s engineering could overcome the mechanical reason for separating them, but it would be expensive to do and would make repair much more expensive as well. Think Tesla Cybertruck on that.