Justin Loeffler planted a sorghum field in Hawk Springs last year, but looks can be deceiving. The field of sorghum is not for forage production or livestock. It’s a Cowboy State hemp field of dreams.

Loeffler chose sorghum because the plant is as thirsty for nutrients as corn, though more drought tolerant. Sorghum was the Hawk Springs farmer’s way of wiping the slate clean for his new field, before planting hemp variety trials this spring.

Loeffler’s ultimate quest is to identify the best varieties for Wyoming hemp, whether the desired end product is fiber, grain or CBD oil.

For right now, though, Loeffler is focusing on all things fiber.

Watch And Learn

“We’re going to throw some grain varieties out in the research field farm, just to kind of watch them and learn,” Loeffler told Cowboy State Daily. “But right now, the fiber varieties are what I’m interested in, and I want to grow varieties that are specific.”

Hemp fibers are not one size-fits-all. There’s an incredible diversity.

“So, if we have a plywood company and/or a hempcrete company, we’ve got a harder variety over here that has a better hurd content.”

Hurd is the fibrous woody inner part of the stalk of a hemp plant.

If the purpose of hemp is for reclamation, on the other hand, such as absorbing an oil spill, or controlling soil erosion, there are fiber varieties with better absorbency instead of strength.

“So, we’re going to start doing onsite trials to fulfill contracts based on what people want,” Loeffler said.

Under The Hemp Hood

But it’s not just in the research plot where Loeffler is testing hemp varieties. He’s also experimenting with processing equipment to figure out which hemp varieties will produce what raw materials, and in what range of sizes and quality.

Before he could get to this point, though, he had to overcome a serious lack of affordable hemp processing equipment.

This was not an insignificant challenge. The first machine he tried adapting to hemp processing was meant for disintegrating railroad ties, but didn’t survive mature hemp, which produces a very woody stalk. This is where the fiber mainly comes from.

The equipment most people are buying to process hemp fiber comes from Europe and costs $40 million. Not only is the price tag unfortunate, Loeffler said, but the machines don’t process a whole lot of hemp either.

“So, we just took the box and we threw it away,” Loeffler told Cowboy State Daily. “Because the box contained European equipment, you know, foreign equipment that you couldn’t really work on.”

Instead, Loeffler took a variety of components that were manufactured for other industries, modified them, and then welded them together for his own purposes.

Not only did he beat the price tag associated with European equipment, but he can now process a larger volume, and he has figured out ways to control the particle size as well. That’s given him a good base to serve customers with different grades of hemp.

“We need lots of processing, and so that’s what we built,” Loeffler said. “We are a fiber mill and packaging facility.”

Missing Connection

Since the federal 2014 Farm Bill opened the door to hemp production, there were farmers almost immediately interested in growing it.

That’s understandable given how drought-tolerant hemp is and how well it works in the wheat rotations that are so important to the cattle industry. Hemp also resists pests and needs little fertilizer. It’s economical — if markets can be found.

Businesses, meanwhile, have all kinds of ideas for hemp in the marketplace.

They want to make insulation, concrete substitutes, premium textiles, 3D printing materials — and that’s not even accounting for all the applications for hemp seeds in the health food sector, or the CBD oil pressed from its flowers that many believe may have medical applications.

But businesses with all those ideas need someone to break down the product that farmers grow and supply it in a variety of formats, ranging from fine dusty particles to jagged pieces that resemble horse bedding.

Not only that, they need those components supplied by the semi-truckload, not by the teeny, tiny grocery bag.

“So that’s what we do here,” Loeffler said. “Get it down to its basic components like a grain elevator, and then sell those components off to people that are going to invent a block-making machine, or they’re going to make hardwood flooring, or whatever it is.”

Bedding Bridge

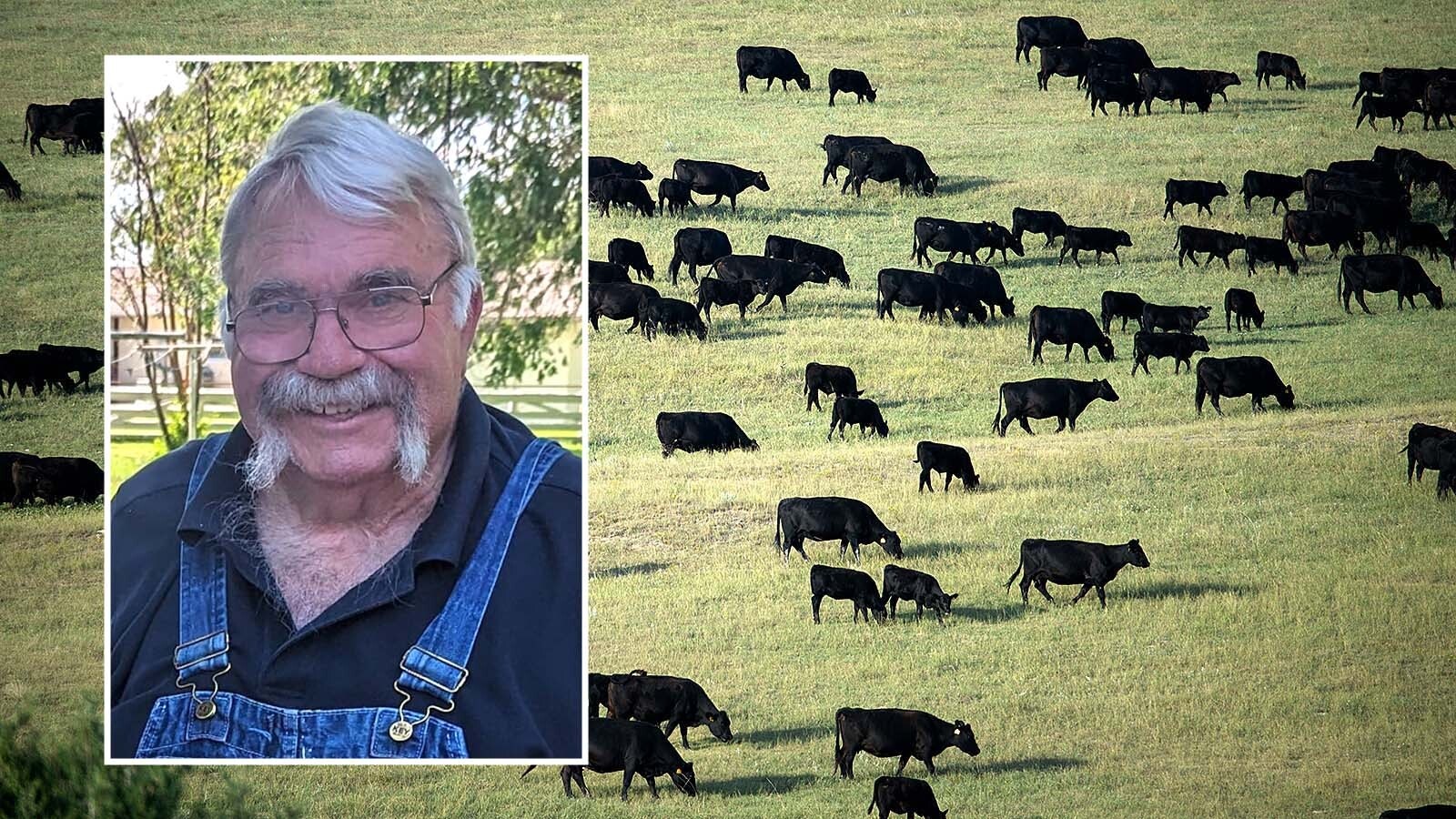

Eventually, Loeffler foresees providing hemp in a wide variety of grades, but for now his main product has been premium bedding for livestock, ranging from horses to chickens.

Bedding is a perfect bridge for experimenting with a wide range of hemp sizes and quality, since different sizes are needed for different-sized animals.

“Poultry right now is a hot topic,” Loeffler said, thanks to high egg prices. “There are a lot of folks that are like, ‘Nope, we’re going to grow our own chickens.’”

Hemp, Loeffler said, makes really good premium bedding.

“It’s four times more absorbent than wood chips,” he told Cowboy State Daily. “It’s antimicrobial. It’s, you know, it helps on respiratory because it doesn’t have all the phenols and toxins that wood shavings have. It’s easy to clean up, and it lasts for a very long time.”

The longevity of the bedding is what helps it stand out from other options, Loeffler added.

“Pine shavings, pellets and all those things, you’re not going to get hardly any use out of it,” he said. “You’re cleaning stalls every day. Equine bedding, you’re going to get almost four times the absorbency and about four times the length on it. And it reduces all the ammonia smells. That’s why all the chicken people want it. It has benefits out the wazoo.”

Over time, Loeffler believes that hemp bedding will prove to be cheaper than less expensive options, because it lasts so much longer.