A sizable piece of farming equipment has been the talk of the agriculture industry since the beginning of the year.

Rumors of an iconic powerful tractor many farmers grew up with making a return to production has had soil evangelists salivating for years.

Then last week, there it was – all 70,000 pounds of it on display, as Big Bud created a huge buzz at Con Expo in Las Vegas.

Biggest And Baddest

Anyone growing up in the Midwest remembers the legendary tractor made by Ron Harmon and the Northern Manufacturing Co. An estimated 550 tractors were built and sold from the 1970-80s, with the last run in 1991.

The high-horsepower articulated tractors were some of the biggest and baddest in the field, tugging a 35,000-pound cultivator down rows at an acre-a-minute.

They were heavy-duty, American-made workaholics designed for megafarms like those in the Canadian wheatbelt and the vast Western plains spreads where farmers could be found plowing not the remote back 40, but the back 400.

These machines were cherished for holding their value, and many are still in use.

Most of all, farmers loved them for the ease with which they could be worked on.

And they were gigantic.

The Big Bud 747, a one-off that rolled out of the factory in 1977, is considered the largest farm tractor in the world. It’s so swole, it makes an International Harvester look like a Mini Cooper.

The Big Bud 747 weighs in at 135,000 pounds fully ballasted and its 1,000-gallon fuel tank topped off. At 1,100 horse power, nothing in the American heartland can touch it.

But by the mid-1990s, the 747 went the way of the dodo, as did the rest of the line when United Tire Co. of Canada went out of business. It was the only manufacturer making the 8-foot-high tires large enough for Harmon’s beasts.

Without tires, demand for the monster tractor slowly dried up.

Today, that one-of-a-kind Big Bud 747 sits outside the Big Equipment Co. (Harmon’s reborn manufacturing business based in Havre, Montana) as a testament to man and machine.

Bud Is Back

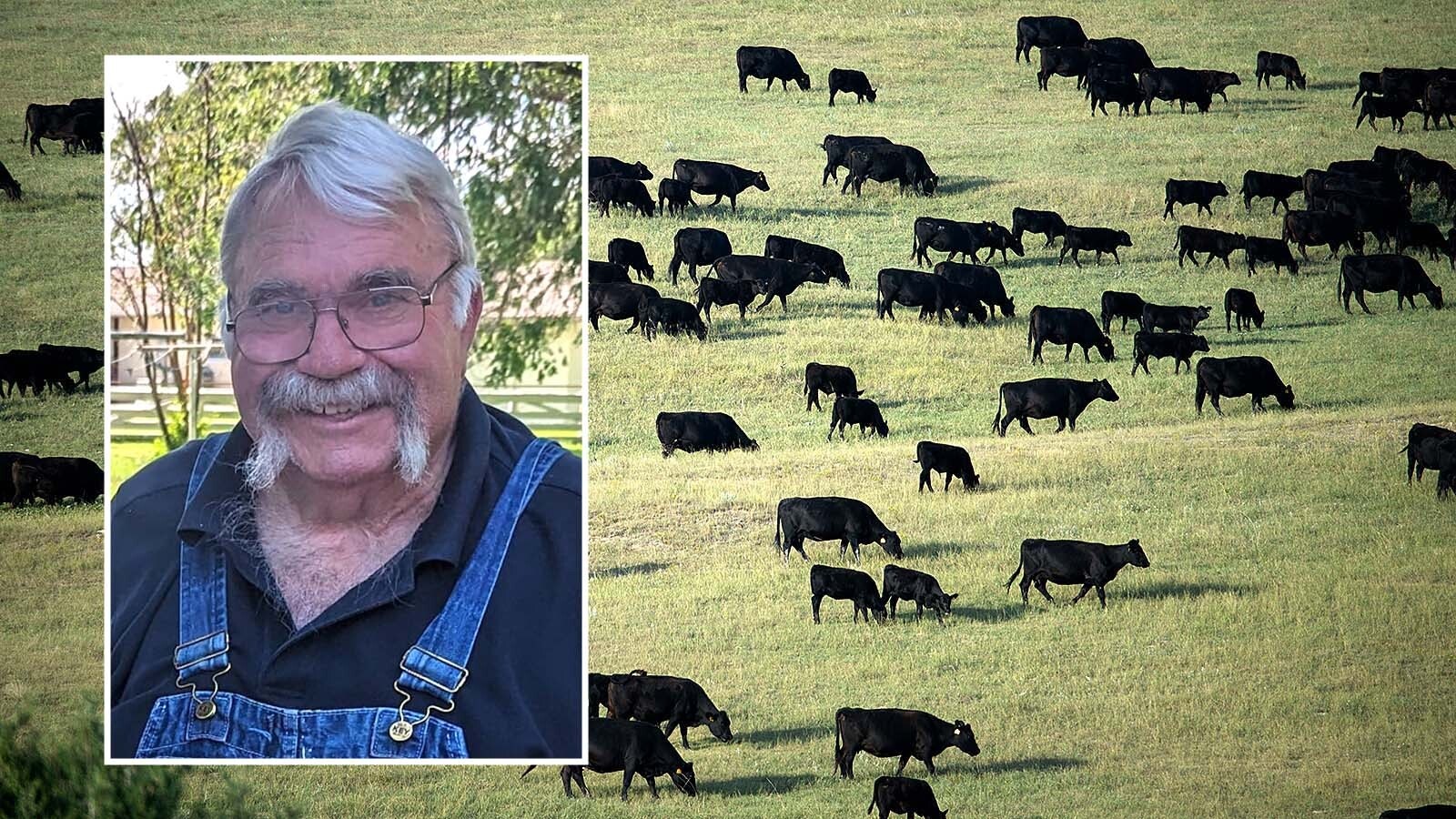

Fast-forward to earlier this year when Harmon had a notion the iconic tractor is due for a return.

Following feedback from farmers, he thinks the time is right to get Big Bud back in the field.

“I’ve been in business since ’74. Back then there were 10 or 15 manufacturers. Today, we’re down to just three. Only one is American-owned, and that’s John Deere,” Harmon said of the tractor industry.

Lack of competition and advances in technology has made life more difficult for end users. Proprietary technology and parts, computer-driven components and complicated service manuals means when farmers have a breakdown in the field, they often must wait weeks or months for available parts or a specially trained mechanic to show up wielding a laptop.

There is nothing Harmon wants more than to give farmers control while selling them a tractor.

Big Buds start with a rugged 1.5-inch-thick frame and components like the transmission and gearbox are easy to access.

“What we are offering is to get back to a tractor that is ruggedly and simply built that anyone can work on,” Harmon said. “Everything slides out of the tractor. It’s really the complete opposite of what we see going on in the industry today.

“It puts the farmer back in control. After all, he’s the guy that writes the check for it.”

Reinventing Reliability

The all-new Big Bud will be modelled off blueprints from the original best-sellers Big Bud 500 and the 700. It will feature an 18-liter Cat engine that will be good for 650 to 750 horsepower.

This scaled-down old-school Big Bud will still be one of the largest farm tractors on the planet. Many of the parts required to build and repair it will come from the mining sector, including its meaty 85,000-pound axels.

“We use largely Cat components. Our criteria is we like to see proven technology and parts out there for 10-15 years or more. Anything new to the market we aren’t interested in,” Harmon said.

While the reborn Big Bud is a back-to-basics piece of machinery, it will not be without some creature comforts.

A state-of-the-art redesigned AGCO cab should provide the kind of fingertip control most operators have grown accustomed to without creating a spaceship-style motherboard that controls everything.

“We all like electronics, but what you won’t see in our tractors is a master computer system special to Big Bud that operates everything,” Harmon said. “Any time you limit the owner or the independent mechanic, it further strains the ability of whoever the closest dealer is; the ability to locate a part or find time to get an authorized technician out to fix it.

“From the beginning, we set out to prove you can still build a piece of equipment in 2023 that anyone can build or work on.”

Fixing The Industry

Servicing farm equipment is something Harmon and his employees know all about.

For the past four decades, Big Equipment has been in the business of repairing and rebuilding large tractors – many of them Big Buds still in use.

Several years ago, Harmon decided to partner with the Rome Plow Co. based in Cedartown, Georgia, to reintroduce an American-made tractor that would hold its value because of its rugged durability and versatility.

Those plans were put on ice after a fire Christmas Eve 2017 completely razed the hometown plant in Havre.

But Harmon is not a man easily put off by disappointment. Last week at Con Expo in Las Vegas, proof of his dream and the rebirth of a legend was the talk of the industry as thousands marveled at the shiny new prototype.

And there’s more where that came from.

“We have several fabricated frames ready to go,” Harmon said.

Production will be done out of a leased facility while Harmon rebuilds his own factory.

“Our production will be held to match demand. Demand seems to be pretty high to us right now,” he said. “We can get maybe 30-40 tractors out of the facility we’ve got now.”

Harmon expects to roll out 10 Big Buds in 2023 to start. Tractors sell more tractors, so he hopes to get back to the days when his company was churning out 120 tractors a year at peak build.

“We want to be strategic,” he added. “We can probably sell all our own tractors right up here in Montana. But that’s not the point. We want to spread them out across the country. Let people see what these things are capable of.”

New-Age Old School

Make no mistake, what Harmon is doing is big, perhaps even bigger than the Big Bud 747.

He’s not simply remarketing a machine known for its old school durability after a 40-year hiatus. Harmon’s reintroduction of the Big Bud is a gamechanger.

In a world that has experienced consolidation of manufacturers of nearly everything we buy and use to the point of near monopolies, and acknowledging designed obsolescence is now the standard, a little machinery shop in Montana is set to revolutionize the manufacturing industry.

If the return of Big Buds proves successful – if these sturdy American-made tractors prove as functional, standardized, serviceable and long-lasting as they’re billed to be – it will mark a return to common sense in engineering and American agriculture.